Regardless of the method used – machine grinding, sharpening steel or manual sharpening tools – good knives must be reground regularly so that they stay sharp for a long time and maintain the quality of the cutting edge. However, with a little practice and the appropriate grinding tools the cutting edge will maintain its quality for a long time. Regular regrinding and polishing guarantee sharp blades for daily use.

Top quality knives are characterised by an extremely durable cutting edge and by high resilience.

Nevertheless, in daily use a knife does meet with resistance and even the sharpest of cutting edges will wear with use. Regular, correct resharpening ensures that the cut is always sharp. A variety of grinding methods can be used for sharpening knives, ranging from manual sharpening to machine grinding.

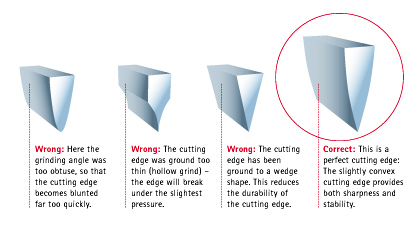

To achieve a sharp cutting edge the blade is ground in a slightly half-rounded shape towards the cutting edge. In technical terms this is called a slightly convex grind. The cutting edge becomes increasingly flatter with grinding and sharpening.

|

| The correct grind |

The crucial factor for sharpness is the correct grinding angle. Depending on the type of knife, the grinding angle between the cutting edge and the grinding tool will be around 20°.

The final sharpness of every good knife is achieved through two work processes. The initial rough grind produces a thicker burr or edge. In the second process this edge is polished and thereby smoothed. In the course of daily work the edge is centred and smoothed again with a sharpening steel or a manual sharpening tool. The knife remains sharp for longer and does not require regrinding so frequently.

The crucial factor for sharpness is the correct grinding angle. Depending on the type of knife, the grinding angle between the cutting edge and the grinding tool will be around 20°.

The final sharpness of every good knife is achieved through two work processes. The initial rough grind produces a thicker burr or edge. In the second process this edge is polished and thereby smoothed.

In the course of daily work the edge is centred and smoothed again with a sharpening steel or a manual sharpening tool. The knife remains sharp for longer and does not require regrinding so frequently.

Manual Sharpening

When a classic sharpening steel is used a few even strokes on each side alternately are usually sufficient for the knife to regain its sharpness. The force used to press the knife against the steel depends on the degree of wear on the blade. The process is only continued until the knife has regained its sharpness. Additional strokes afterwards do not increase the degree of sharpness.

The angle between the sharpening steel and the knife should be about 20°. The knife is held with the cutting edge diagonal to the steel as it is drawn across it. The knife is sharpened alternately left and right with a loose movement initiating from the wrist and in as large an arc as possible.

No pressure, a little pressure or a great deal of pressure may be used when sharpening, according to whether the cutting edge is new or has just been ground, is slightly worn down or severely worn down.

But even the best cutting edge becomes worn with heavy use. The cutting edge disappears and cannot be restored with the sharpening steel. The knife must then be reground by machine.

Any question, do not hesitate to put in contact with us: www.mercafilo.es

via Giesser Messer